Country selector

North America

Country Selector: North America

Ascom’s IoT and Sensor Integration solutions lets you gather and send the right information to the right people at the right time – making production more efficient and cost-effective, as well as helping you identify further potential gains.

Today's industry makes increasing use of data from sensors to help monitor and optimize both the production process and the production equipment. This data can help your management and staff find efficiency gains as well as identify equipment and maintenance issues before they lead to costly unplanned stops or emergency shutdowns.

But collecting and making the best use of sensor data can be a real challenge. The volume of data is often massive, stored centrally and sometimes needs a data engineer to understand and utilize it. However, to make the greatest and most valuable efficiency gains, the data ideally should be aggregated and distributed to the mobile workforce of production operatives and maintenance engineers.

Faced with this challenge, your production teams need a solution that lets them smoothly and seamlessly integrate sensor data from their systems and mobilize the data by sending it to the right people at the right time. Increasing operational efficiency by correcting problems before they cost money, alerting only the relevant people at the relevant locations, and helping managers analyze the data and identify trends to make further potential gains.

The challenge is that all of these puzzle pieces of the Internet of Things – the components that you need in your digital transformation – need to start to come together with business processes. So far, they’re not connected.

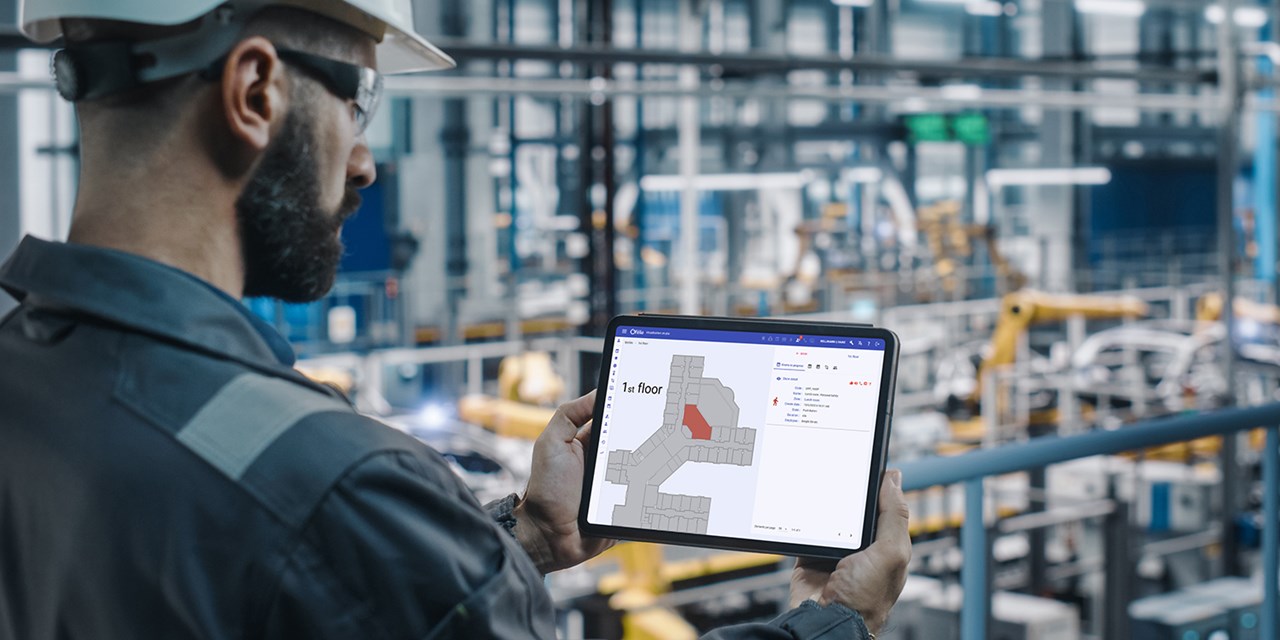

Ascom provides a truly open solution for IoT sensor integration and data distribution. The solution is centered around driver-based integration through industry standard protocols, mobile devices with in-built features such as real-time location technologies, alarm dashboards, incident mapping and mobile response workflows. With the goal to boost situational awareness, the solution ensures managers can easily access and analyze the data while staff can more easily and confidently handle increasingly complex and highly automated production lines, secure in the knowledge that any alerts will be sent to the right person in real time.